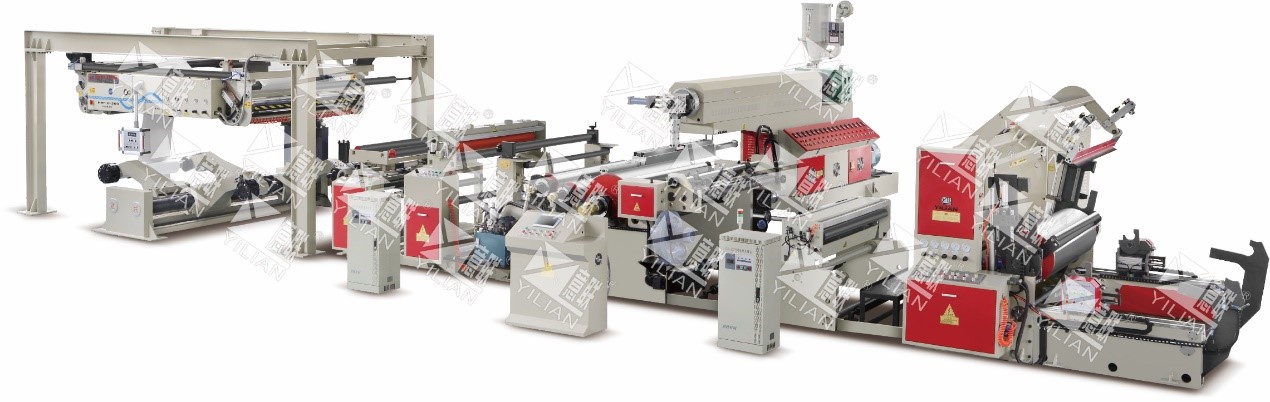

WSFM1300C Takarda Ta atomatik PE Extrusion Rufe Machine

| Suit laminating guduro | LDPE, PP da dai sauransu |

| Suit tushe kayan | takarda (80-400g/m²) |

| Max gudun inji | 300m / min (aiki gudun ya dogara da shafi kauri, nisa) |

| Faɗin sutura | 600-1200, jagora nisa: 1300mm |

| Kauri mai rufi | 0.008-0.05mm (Dutse guda ɗaya) |

| Kuskuren kauri mai rufi | ≤±5% |

| Kewayon saitin tashin hankali ta atomatik | 3-100kg cikakken gefe |

| Matsakaicin adadin extruder | 250 kg/h |

| Nadi mai sanyaya mahadi | ∅800×1300 |

| Diamita mai dunƙulewa | ∅110mm rabo 35:1 |

| Matsakaicin diamita mara iska | ∅1600mm |

| Matsakaicin diamita mai juyawa | ∅1600mm |

| Unwind takarda core diamita: 3 ″ 6 ″ da Rewind takarda core diamita: 3″ 6″ | |

| Extruder yana tuƙi da 45kw | |

| Jimlar iko | kusan 200 kw |

| Nauyin inji | kimanin 39000kg |

| Girman waje | 16110 mm × 10500 mm × 3800 mm |

| Launin jikin injin | Grey da Ja |

1. Unwind part (tare da PLC, servo unwinding)

1.1 Firam mara nauyi

Tsarin: Firam mara nauyi mara nauyi

Silsilar BA splicer ta samar da wani muhimmin sashi na layin lamination kuma an shigar da shi a kan nadi a ƙarƙashin tsarin gada. Yana ba da damar ci gaba da gudanar da nadi na takarda da ke akwai zuwa takarda ta gaba ba tare da dakatar da samarwa ba.

A cikin firam ɗin gefen splicer akwai kan splicing 2 mai motsi da sashin tallafi na tsakiya mai motsi. Sama da shi akwai nadi 2 nip.

Nadin kaftin, jujjuyawar raɗaɗi da tsarin raye-raye biyu suna samar da sashin tara takarda wanda zai iya tara takarda har sau 4 tsayin splicer.

Ana sarrafa na'ura ta hanyar aikin aiki akan na'ura

Gudun haɗin takarda Max.300m/min

a) lokacin da ƙarfin takarda sama da 0.45KG/mm, max. 300m/min;

b) lokacin da ƙarfin takarda sama da 0.4KG/mm, max. 250m/min;

c) lokacin da ƙarfin takarda sama da 0.35KG/mm, max. 150m/min;

Faɗin takarda

Max. 1200mm

Min. 500mm

Saurin CE-300

Max. 300m/min

Bayanan pneumatic

Saita matsa lamba 6.5 bar

Min. matsa 6 bar

Samfura CE-300

Ƙarfin wutar lantarki 3.2kVA, 380VAC/50Hz/20A

Sarrafa ƙarfin lantarki 12VDC/24VDC

1.1.1 Independent na'ura mai aiki da karfin ruwa shaft spindle matsa hannu nau'in biyu aiki-tasha unwinding, ba tare da iska shaft, na'ura mai aiki da karfin ruwa loading, ajiye farashin loading inji tsarin. Atomatik AB shaft auto reel canji, ƙarancin sharar kayan abu.

1.1.2 Max. diamita mai kwance: ¢1600mm

1.1.3 Kewayon saitin tashin hankali ta atomatik: 3-70kg cikakken gefe

1.1.4 daidaitaccen tashin hankali: ± 0.2kg

1.1.5 takarda core: 3" 6"

1.1.6 Tsarin kula da tashin hankali: nau'in nau'in mai gano tashin hankali ta daidaitaccen tashin hankali na ganowa na potentiometer, ikon tsakiya na PLC mai shirye-shirye

1.1.7 Drive kula da tsarin: PIH Silinda birki, da Rotary encoder feedback da sauri, daidaitaccen matsa lamba regulating bawul rufaffiyar madauki iko, programmable mai sarrafawa PLC Karkasa iko

1.1.8 Saitin tashin hankali: Ta hanyar madaidaicin matsa lamba mai daidaita saitin bawul

1.2 Ajiye nau'in karban atomatik, na'urar yanke

1.2.1 Ajiyewa ta hanyar buffer motor pneumatic, tabbatar da kwanciyar hankali lokacin ɗaukar takarda.

1.2.2 raba sabon tsarin

1.2.3 PLC auto lissafta sabon shaft gudun rotary, da kuma ci gaba da gudu tare da babban layi gudun

1.2.4 Karɓi abin nadi latsa, abin yankan karya abu

1.2.5 Nadi canza ƙararrawa,: diamita aiki lokacin da kai 150mm., Na'ura za ta ƙararrawa

1.3 Gudanar da Gyara: Tsarin sarrafa hoto (tsarin bst)

2. Corona (Yilian customized)

Ikon maganin Corona:20kw

3. Naúrar lamination na ruwa:

3.1 Rollers uku laminating fili tsarin, baya danna abin nadi, na iya sa fili abin nadi bear ƙarfi ko da, fili m.

3.2 Cire abin nadi na siliki na roba: samfuran fili yana da sauƙin hangowa daga abin nadi mai sanyaya, na'ura mai aiki da karfin ruwa na iya dannawa sosai.

3.3 The mai lankwasa yi film lankwasa tsarin,: iya yin fim m turawa

3.4 Haɗaɗɗen kayan abinci daidaita abin nadi na iya shawo kan kauri kayan fim mara daidaituwa da sauransu

3.5 Babban matsi mai busawa yana tsotse gefuna da sauri.

3.6 Abun abin nadi mai tsinkewa

3.7 Motoci masu dogaro da kai ne ke tuka abin nadi

3.8 Motar mai tuƙi mai haɗaɗɗiya ana sarrafa ta mai sarrafa mitar Japan

Musamman:

(1) nadi nadi: 800 × 1300mm 1pcs

(2) nadi na roba: 260 × 1300mm 1pcs

(3) latsa abin nadi: ¢ 300 × 1300 mm 1pcs

(4) Silinda mai hadawa:¢63 × 150 2pcs

(5) kwasfa nadi:¢130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1 set

(7) 11KW Frequency Converter (JAPAN YASKAWA)

(8) mai haɗawa: (2.5"2 1.25"4)

4. Extruder (auto tsawo daidaitawa)

4.1 dunƙule diamita: ¢ 110, Max extruder game da: 250kg / h (Japan fasahar)

4.2 T-die (Taiwan GMA)

4.2.1 Mold nisa: 1400mm

4.2.2 Mold tasiri nisa: 500-1200mm

4.2.3 Mold lebe rata: 0.8mm, shafi kauri: 0.008-0.05mm

4.2.4 Kuskuren kauri mai rufi: ± 5%

4.2.5 Electric dumama tube ciki dumama, dumama high tasiri, zafin jiki karuwa da sauri

4.2.6 Gabaɗaya ruɗewa nassi, Daidaita faɗin kaya

4.3 Na'urorin cibiyar sadarwa masu saurin canzawa

4.4 Gaba da baya tafiya, na iya ɗaukar Trolley ta atomatik, kewayon ɗagawa: 0-100mm

4.5 Mold 7 wuraren kula da zafin jiki. Screw ganga 8 sashe kula da zafin jiki. haši 2 yankin kula da zafin jiki rungumi infrared dumama raka'a.

4.6 Babban ƙarfin Rage Akwatin Gear, HARD TOOTH (Guo tai guo mao)

4.7 Digital zazzabi mai sarrafa atomatik zazzabi

Manyan sassa:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW mitar Converter (JAPAN YASKAWA)

(3) Digital zazzabi mai kula 18pcs

(4) Motar tafiya 1.5KW

5.Pneumatic Round wuka trimming na'urar

5.1 Trapezoidal dunƙule juzu'i daidaita na'urar, canza yankan nisa na takarda

5.2 Mai tsinkayar Matsala ta huhu

5.3 5.5kw babban matsa lamba gefen sha

6. Rewinding Unit: 3D nauyi tsarin tsarin

6.1 Tsarin Juyawa:

6.1.1 Gogayya irin lantarki biyu tashoshi rewinding inji, high-gudun atomatik yankan da daukana gama abu, atomatik saukewa.

6.1.2 Max. Rewinding diamita: ¢ 1600 mm

6.1.3 mirgine gudun: 1r/min

6.1.4 tashin hankali: 3 - 70kg

6.1.5 Daidaitaccen tashin hankali: ± 0.2kg

6.1.6 takarda core: 3 ″ 6 ″

6.1.7 Tsarin Kula da Hankali: Kushin Silinda yana yawo da tsarin nau'in abin nadi mai iyo, ana gano tashin hankali ta madaidaicin potentiometer, kuma PLC mai sarrafa shirye-shirye yana sarrafa tashin hankali. (Japan SMC low gogayya Silinda) 1 saiti

6.1.8 Tsarin Kula da Tuba: Motar motar 11KW, saurin amsawa mai jujjuyawa, Senlan AC inverter dual rufaffiyar madauki iko, mai sarrafa shirye-shirye PLC sarrafa tsakiya. 1 saiti

6.1.9 Saitin Tsanani Tsaye: Saitin Matsalolin Matsalolin Matsala (SMC na Japan)

6.1.10 Taper tashin hankali saitin: sabani saita ta kwamfuta allo, PLC iko, juyi ta lantarki / iska rabo (Japan SMC)

6.2 Na'urar Ciyarwa ta atomatik

6.2.1 Splicing Support Rollers ana sarrafa su ta hanyar PLC don fitar da motar don riƙe kayan daga abin nadi.

6.2.2 Na'urar Cutter Mai Zaman Kan Ruwa

6.2.3 PLC lissafin atomatik na tsarin ɗauka, an kammala maye gurbin ƙarar tare da maɓalli

6.2.4 Aiki na Tallafin abin nadi, Yanke kayan, Sake saiti, da dai sauransu An Kammala ta atomatik

6.2.5 Takaddun bayanai

(1) Abin nadi: ¢700x1300mm 1 mashaya

(2) Motar iska: 11KW (Shanghai Lichao) 1 saiti

(3) Akwatin kaya mai jujjuyawa: mai taurin saman helical gear rage (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 saiti

(5) Akwatin kayan aikin nadi: 1 saitin ƙarfi

(6) Mai rage saurin gudu: haƙori mai wuya 1 saitin ƙarfi

(7) Mai rage saurin tafiya mai jujjuyawa: saitin ƙarfi 1

(8) Tashar ruwa mai watsa ruwa

7.Auto iska shaft puller

8.Drive Sashin

8.1 Babban motar, bel mai watsawa yana ɗaukar bel ɗin aiki tare

8.2 Haɗawa, jujjuyawar da injin kwance: Driver bel ɗin ɗaukar kayan baka, sarkar da watsa bel ɗin aiki tare.

8.3 Babban akwatin kayan tuki: Rufe man da aka nutsar da mai, Tsarin watsa kayan aikin layin helical

9.Control Unit

Majalisar lantarki mai zaman kanta, sarrafawa mai mahimmanci, wurin da aka haɗa tare da aikin hukuma mai kulawa. Na'ura mai sarrafa kansa ta amfani da saitin na'urar PLC (hollsys) tare da babban ikon sarrafawa, da siginar tattaunawa na injin-na'ura ta amfani da hanyar sadarwa ta hanyar sadarwa tsakanin mu'amala. PLC, naúrar extrusion, mu'amalar tattaunawa tsakanin injina da injin tuƙi da haɗa tsarin sarrafa atomatik. Ga kowane sigogi za a iya saita, tare da lissafin atomatik, ƙwaƙwalwar ajiya, ganowa, ƙararrawa, da dai sauransu Za a iya tashin hankali na na'urar nuni na gani, gudun, kauri mai rufi, gudun da yanayin aiki daban-daban.

10. wasu

11.1 Jagora Roller: Hard anodization na aluminum gami jagoran jagora, tsarin motsi

11.2 Low irin ƙarfin lantarki na'urar don Faransa Schneider, omron Japan, da dai sauransu.

11.bangare iri

11.1 PLC (Beijing Hollysys)

11.2 Touch Screen (TAIWAN)

11.3 mai canzawa: Japan Yaskawa

11.4 Babban Mota: SHANGHAI

11.5 low gogayya Silinda (Japan SMC)

11.6 AC CONTACTOR (Schneider)

Maɓallin 11.7 (Schneider)

11. Static mixer (Taiwan)

11.9 Silinda matsa lamba regulating bawul (Taiwan)

11.10 Magnetic musayar bawul (Taiwan)

11.11 daidaitaccen matsa lamba daidaita bawul (SMC)

12.Customer kai yana samar da kayan aiki

12.1 Wurin kayan aiki da tushe

12.2 Abubuwan samar da kayan aikin injin lantarki

12.3 Samar da ruwa ga kayan aikin injin ciki da waje daga ƙofar (mai siye yana shirya mai sanyaya ruwa)

12.4 Isar da iskar gas zuwa injin da aka saita a ciki da waje na stomatal

12.5 Fitar bututu da fan

12.6 Tattara, lodawa da sauke kayan tushe kayan aikin da aka gama

12.7 Sauran wuraren da ba a jera su a cikin kwangila ba

13. Jerin kayayyakin gyara:

| A'a. | Suna | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Mai sarrafa zafin jiki | Omron |

| 3 | Micro-regulating bawul | 4V210-08 |

| 4 | Micro-regulating bawul | 4V310-10 |

| 5 | canjin kusanci | 1750 |

| 6 | m gudun ba da sanda | 150A和75A |

| 7 | canjin tafiya | 8108 |

| 10 | naúrar dumama | 90*150mm,700W |

| 11 | naúrar dumama | ϕ350*100mm, 1.7KW |

| 12 | naúrar dumama | 242*218mm, 1.7KW |

| 13 | naúrar dumama | 218*218mm, 1KW |

| 14 | naúrar dumama | 218*120mm,800W |

| 15 | Maballin Schneider | ZB2BWM51C/41C/31C |

| 16 | zakara | |

| 17 | Babban tef ɗin zafin jiki | 50mm*33m |

| 18 | telflon tape | |

| 19 | Corona roller cover | 200*1300mm |

| 20 | Copper takardar | |

| 21 | allo tace | |

| 22 | Zagaya tsaga | 150*80*2.5 |

| 23 | mai haɗa pneumatic | |

| 24 | bindigar iska | |

| 25 | hadin gwiwa ruwa | 80A da 40A |

| 27 | sukurori da sauransu | |

| 28 | ja sarkar | |

| 29 | akwatin kayan aiki |

Babban sassa da hoto:

Unwinder (Auto splicer) → jagorar gidan yanar gizo → Maganin Corona → Extrusion da haɓaka ɓangaren Edge Trimming → Rewinding